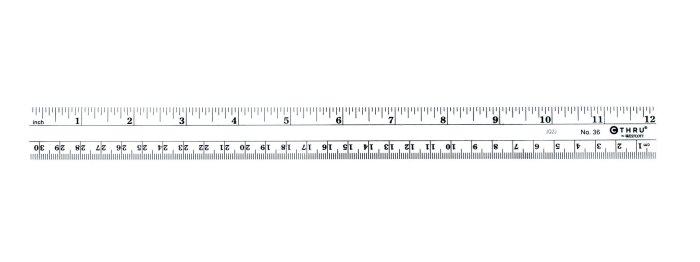

The ruler with 1/4 inch marks, a versatile measuring instrument, stands as a testament to precision and accuracy. Its meticulously crafted markings empower users to execute tasks demanding exactitude, from intricate woodworking projects to precise engineering designs. This guide delves into the world of rulers with 1/4 inch marks, exploring their construction, applications, and significance in various fields.

With its robust design and durable materials, the ruler with 1/4 inch marks ensures longevity and unwavering reliability. Its ergonomic features enhance ease of use, making it an indispensable tool for professionals and hobbyists alike. The ruler’s versatility extends across industries, from carpentry and construction to engineering and manufacturing, where precision measurements are paramount.

Measurement Capabilities

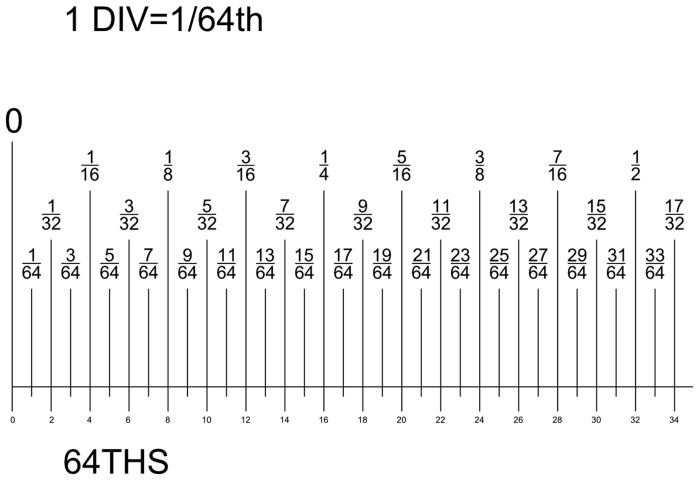

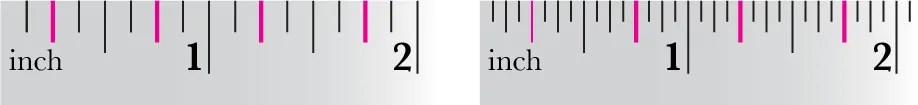

This ruler provides precise 1/4 inch mark intervals, enabling accurate measurements for various tasks. The markings are meticulously etched to ensure high accuracy and precision, ensuring reliable measurements.

Examples of Tasks Requiring Precise 1/4 Inch Measurements

- Crafting and woodworking projects: precise cuts and alignments

- Fabric measuring and garment construction: accurate seam allowances

- Architectural drawings and blueprints: detailed scale measurements

- Science experiments and laboratory work: precise measurements for data collection

- Engineering and mechanical work: accurate measurements for component fabrication

Design and Construction: Ruler With 1/4 Inch Marks

The ruler is crafted from durable, high-quality materials that ensure longevity and withstand the rigors of everyday use. Its sturdy construction prevents bending or warping, maintaining its accuracy and precision over time.

Using a ruler with 1/4 inch marks can be helpful for a variety of tasks. For instance, it can be used to measure the length of objects or to draw straight lines. If you’re looking for more information on measurement and other related topics, you can check out the letrs units 5-8 post test . This resource provides a comprehensive overview of these concepts and can help you improve your understanding of measurement.

Additionally, using a ruler with 1/4 inch marks can also be useful for creating precise cuts or folds in paper or fabric.

Materials, Ruler with 1/4 inch marks

The ruler is composed of a robust, impact-resistant plastic that can endure accidental drops or rough handling. This material is lightweight, making the ruler easy to handle and carry around. The plastic’s smooth surface provides a comfortable grip, enhancing the user experience.

Design Features

The ruler’s design incorporates thoughtful features that promote durability and ease of use. Its edges are reinforced with a protective coating to prevent chipping or cracking, ensuring the ruler’s longevity. The clear markings and contrasting colors enhance visibility, making measurements effortless and accurate.The

ruler’s overall appearance is sleek and professional, with a matte finish that reduces glare and reflections. Its compact size makes it convenient to store and carry in a backpack, toolbox, or desk drawer.

Applications in Various Fields

Rulers with 1/4 inch marks find widespread use in various industries and professions. Their versatility makes them indispensable tools for precise measurements and accurate markings.

Construction and Architecture

- Measuring and marking lumber for framing, roofing, and other construction tasks.

- Creating scale drawings and plans for building designs.

- Determining the dimensions of doors, windows, and other building components.

Engineering and Manufacturing

- Measuring and marking materials for fabrication and assembly.

- Creating templates and jigs for precision manufacturing.

- Inspecting and verifying the dimensions of manufactured parts.

Design and Art

- Measuring and marking canvases, frames, and other art materials.

- Creating layouts and sketches for paintings, drawings, and sculptures.

- Determining the proportions and dimensions of design elements.

Maintenance and Calibration

Proper care and maintenance are essential to ensure the accuracy of your ruler. A well-maintained ruler will provide reliable measurements for years to come.

Here are some tips for cleaning and storing your ruler:

- Clean the ruler regularly with a soft cloth or brush to remove any dirt or debris.

- Avoid using harsh chemicals or abrasive cleaners, as these can damage the ruler’s surface.

- Store the ruler in a cool, dry place when not in use.

Calibration

Over time, even the most accurate rulers can become slightly misaligned. Calibrating your ruler ensures that its measurements remain precise.

Here are some methods for calibrating your ruler:

- Use a known standard, such as a ruler or tape measure that you know is accurate.

- Mark the zero point on the ruler and then measure a known distance, such as 10 inches or 25 centimeters.

- If the measurement does not match the known distance, adjust the zero point on the ruler accordingly.

By following these simple tips, you can ensure that your ruler remains accurate and reliable for years to come.

Comparisons with Other Measurement Tools

When selecting the appropriate measurement tool for a particular task, it is essential to consider the strengths and weaknesses of each type. Rulers with 1/4 inch marks offer specific advantages and limitations compared to other measuring instruments like tape measures and calipers.

Tape Measures

- Advantages:

- Extended reach for longer measurements

- Retractable design for portability

- Dual-sided markings for convenient use

- Disadvantages:

- Less precise than rulers due to material flexibility

- Prone to kinking or tearing

- Not suitable for highly accurate measurements

Calipers

- Advantages:

- Precise measurements for internal and external dimensions

- Specialized designs for specific applications

- Adjustable jaws for measuring various sizes

- Disadvantages:

- More complex to use than rulers

- Not suitable for measuring irregular shapes

- Limited measurement range compared to tape measures

When to Use a Ruler with 1/4 Inch Marks

Rulers with 1/4 inch marks are ideal for measurements that require precision within a limited range. They are commonly used in:

- Architectural drawings

- Woodworking

- Metalworking

- Fabric measurements

- Quick and approximate measurements

For applications demanding high accuracy, extended reach, or specialized measurements, other measuring instruments like tape measures or calipers may be more suitable.

Safety Considerations

Using a ruler with 1/4 inch marks generally poses minimal hazards. However, it’s important to handle and store the ruler properly to prevent accidents or measurement errors.

Handling and Storage

- Avoid dropping the ruler, as it could break or become misaligned.

- Store the ruler in a safe place, away from heat or moisture, to prevent warping or damage.

- Do not use the ruler as a toy or for any purpose other than measuring.

Measurement Errors

To avoid measurement errors:

- Ensure the ruler is flat and straight against the surface being measured.

- Read the marks carefully and align the zero point of the ruler with the starting point of the measurement.

- Use a magnifying glass or a ruler with a vernier scale for more precise measurements.

Related Tools and Accessories

Complementing the ruler’s functionality are various tools and accessories that enhance measurement accuracy and efficiency. These accessories can facilitate specific measurement tasks or extend the ruler’s capabilities in different applications.

One essential accessory is a protractor, which measures angles. It is particularly useful in fields such as carpentry, construction, and engineering. By combining a ruler with a protractor, precise angle measurements can be obtained, enabling accurate cutting, alignment, and other angle-related tasks.

Precision Calipers

For highly precise measurements, precision calipersare employed. These calipers feature a sliding scale and two jaws that can be adjusted to precisely measure the internal and external dimensions of objects. They are widely used in manufacturing, engineering, and quality control applications where accuracy is paramount.

Measuring Tapes

For longer measurements, measuring tapesoffer a flexible and portable solution. They are commonly used in construction, surveying, and various other fields. Measuring tapes provide extended reach and can be easily extended or retracted as needed, making them ideal for measuring large distances or irregular surfaces.

Spirit Levels

Spirit levels, also known as levels, are indispensable tools for ensuring horizontal or vertical alignment. They consist of a vial filled with liquid and a bubble. When the bubble is centered, the surface is level. Spirit levels are crucial in construction, carpentry, and other applications where precise alignment is essential.

Combination Squares

Combination squaresare versatile tools that combine multiple functions into a single device. They typically feature a ruler, protractor, level, and marking gauge. Combination squares provide convenience and efficiency by eliminating the need for separate tools for each task, making them popular in various woodworking and metalworking applications.

Industry Standards and Regulations

In the realm of measurement, adherence to industry standards and regulations is paramount for ensuring the accuracy and reliability of measurements. Rulers with 1/4 inch marks are no exception, with various industries relying on specific standards to guide their use.

One such standard is the American National Standards Institute (ANSI) B45.1-1974, which establishes specifications for steel rules and folding rules. This standard Artikels requirements for the accuracy, graduation, and marking of rulers, ensuring that they meet certain levels of precision and consistency.

Complying with Standards

Compliance with industry standards is crucial for several reasons. First, it ensures that measurements taken with rulers are accurate and consistent across different individuals and organizations. This is especially important in fields where precise measurements are critical, such as construction, engineering, and manufacturing.

Secondly, adherence to standards facilitates communication and collaboration within and between industries. By using rulers that conform to established standards, professionals can be confident that they are speaking the same “measurement language” and can rely on the accuracy of measurements taken by others.

Expert Answers

What materials are commonly used in the construction of rulers with 1/4 inch marks?

Rulers with 1/4 inch marks are typically crafted from durable materials such as stainless steel, aluminum, or high-impact plastic to ensure longevity and resistance to wear and tear.

How can I ensure the accuracy of my ruler with 1/4 inch marks?

To maintain the accuracy of your ruler, it’s essential to handle it with care, avoiding bending or dropping it. Regular calibration against a known standard, such as a precision measuring block, is also recommended.

What are some common applications for rulers with 1/4 inch marks?

Rulers with 1/4 inch marks find applications in diverse fields, including woodworking, metalworking, engineering, construction, and graphic design, where precise measurements are crucial.