Fretting corrosion is most likely to occur when two metal surfaces in contact experience relative motion, leading to severe damage and compromising structural integrity. This article delves into the intricacies of fretting corrosion, exploring its causes, mechanisms, consequences, and effective prevention strategies.

Understanding the fundamental aspects of fretting corrosion empowers engineers and researchers to develop innovative solutions that enhance the durability and reliability of engineering systems.

Causes of Fretting Corrosion

Fretting corrosion is a type of localized corrosion that occurs when two metal surfaces are in contact and subjected to repeated relative motion. The mechanical and environmental factors that contribute to fretting corrosion include:

Mechanical Factors

- Contact pressure: The higher the contact pressure, the greater the likelihood of fretting corrosion.

- Slip amplitude: The greater the slip amplitude, the greater the likelihood of fretting corrosion.

- Frequency of motion: The higher the frequency of motion, the greater the likelihood of fretting corrosion.

Environmental Factors, Fretting corrosion is most likely to occur

- Presence of moisture: Moisture can act as an electrolyte, promoting the electrochemical reactions that lead to fretting corrosion.

- Presence of oxygen: Oxygen is necessary for the formation of the oxide layer that protects metal surfaces from corrosion. However, in the presence of fretting, the oxide layer can be broken down, exposing the metal surface to further corrosion.

- Temperature: Higher temperatures can accelerate fretting corrosion by increasing the rate of chemical reactions.

Fretting corrosion can occur in a variety of industries, including:

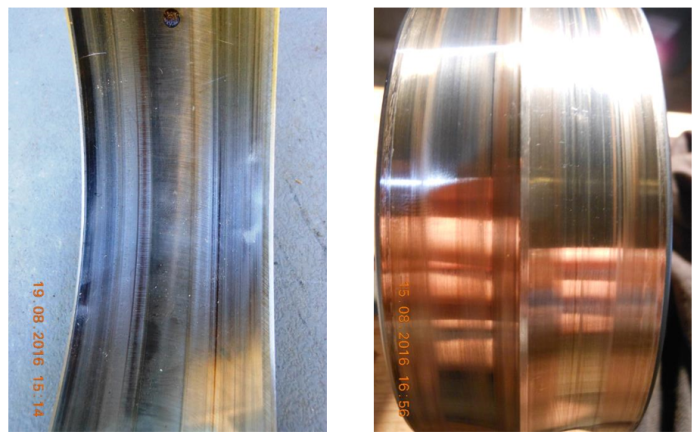

- Automotive industry: Fretting corrosion can occur in bearings, gears, and other components that are subjected to repeated motion.

- Aerospace industry: Fretting corrosion can occur in aircraft components, such as wings and landing gear, that are subjected to high levels of vibration.

- Medical industry: Fretting corrosion can occur in medical implants, such as hip and knee replacements, that are subjected to repeated motion.

Expert Answers: Fretting Corrosion Is Most Likely To Occur

What are the primary factors contributing to fretting corrosion?

Mechanical factors, such as contact pressure and slip amplitude, and environmental factors, such as humidity and temperature, play crucial roles in initiating and sustaining fretting corrosion.

How does fretting corrosion impact material properties?

Fretting corrosion can lead to significant degradation of material properties, including reduced fatigue strength, increased wear, and compromised fracture toughness.

What are the most effective methods for preventing fretting corrosion?

Coatings, surface treatments, and design modifications are commonly employed to prevent fretting corrosion. Proper lubrication and the use of fretting-resistant materials can also be effective.